At ISFH, we do not focus solely on how to increase the efficiency of silicon solar cells. Equally important for us is whether new cell concepts can withstand and be applied under realistic production conditions. Efficiency alone is not sufficient if it can only be achieved under laboratory conditions or requires completely new manufacturing infrastructures in industry.

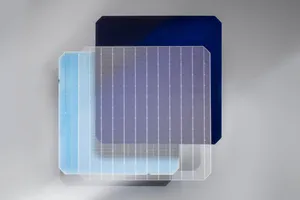

Against this background, we have developed an industrial process sequence for POLO IBC solar cells over recent years. The aim was to combine the known advantages of IBC architectures with a manufacturing approach that closely aligns with existing PERC+ production lines. With the work presented here, we demonstrate that this objective can be achieved.

24.5 percent efficiency with industry-oriented processes

In the current study, we at ISFH achieved, for the first time, an efficiency of 24.5 percent for POLO IBC solar cells on M2 wafers, with independent confirmation. All key process steps were implemented using industry-oriented equipment at ISFH SolarTeC.

The resulting cell parameters show that the combination of SiOx-based passivating contacts, an IBC architecture, and optimized antireflection coatings enables a high voltage level and high current density. At the same time, the process sequence proved robust enough to deliver reproducibly high results.

Technology transfer to industry

A central aspect of our work is its proximity to industrial standards. Only a few steps of the PERC+ process, primarily doping, are replaced by the POLO IBC process. Existing texturing as well as passivation, laser, and screen-printing processes can continue to be used. Together with Kalyon PV, we have therefore begun transferring the POLO IBC process to an existing PERC+ production line. Initial test wafers on M10 Ga-doped Cz wafers show iVoc values of up to 727 mV and confirm the high passivation quality under industrial conditions.

For us, these results clearly demonstrate that this technology is not limited to the laboratory. Existing production lines can continue to be used and gradually upgraded to higher efficiencies.

Why POLO IBC is not the end of development

Despite achieving 24.5 percent, we are aware that the POLO IBC architecture has physical limits. In particular, recombination at the Al BSF contact limits the achievable efficiency to below 25.5 percent.

For this reason, we at ISFH are already working on the next generation, the POLO2 IBC solar cell. This concept replaces the Al BSF contact with a p-type polysilicon passivating contact, enabling passivating contacts for both charge carriers. This creates the basis for higher voltages and efficiencies.

Key results

- POLO IBC solar cells with 24.5 percent efficiency on p-type Cz wafers

- Voc values up to 726 mV for fully processed cells

- iVoc up to 727 mV on M10 test wafers at industrial partners

- POLO2 IBC test structures with iVoc up to 735 mV without metal contacts

- Calculated efficiency potential of 26.4 percent for POLO2 IBC

Why this matters for industry

- Retrofitting existing PERC+ lines with minimal additional effort

- Use of established wet-chemical and PECVD processes

- Reduced recombination at contacts increases voltage and efficiency

- Clear scaling pathway for IBC cell concepts