Innovative industrial-scale manufacturing processes

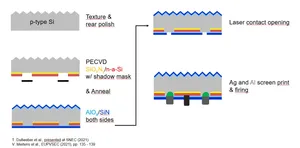

The Industrial solar cells research group develops innovative, mass-production-compatible manufacturing processes for the next generation of silicon solar cells in the areas of PECVD coating, wet chemistry, and screen-print metallization.

A key focus is the PECVD deposition of doped polycrystalline silicon (POLO) – a process that enables excellent surface passivation and low series resistance while maintaining high industrial compatibility. This work lays the foundation for durable and high-performance solar cells that can be efficiently integrated into existing production lines.

High-efficiency POLO IBC solar cells

As part of ongoing research projects in cooperation with equipment manufacturers and solar cell producers, the POLO IBC cell (Interdigitated Back Contact) is being further developed as a promising cell concept for future PV applications, with a focus on higher efficiencies and cost-effective manufacturing processes.

The POLO IBC cell places all contacts on the rear side, minimizing optical losses on the front and improving the cell's current output. The aim is to achieve maximum efficiency with cost-effective fabrication. To this end, we are developing new manufacturing techniques for the low-cost structuring of poly-Si layers using laser ablation or shadow masks. The goal is to scale POLO IBC technology to an industrial level in terms of scalability, throughput, and long-term reliability.

Industry partnerships

In addition to publicly funded projects, the group is also engaged in bilateral industrial collaborations. Together with partners from the PV industry, new IBC solar cell concepts are being developed for specific production environments – covering the entire process from process development to cell characterization.

Projects

Batman

Novel wet-chemical batch processes for future industrial silicon solar cells

M12PV

M12 photovoltaic research infrastructure as a contribution to technological leadership in the production of silicon solar cells

OLIVIA

High-performance, cost-effective IBC solar cells for future PV production in Germany

IBC4EU

Piloting novel cost-competitive bifacial IBC technology for vertical integrated European GW scale PV production value chain

POPEI

Production technologies for high-performance cost-effective IBC solar cells

2Power

Installation of a laboratory for Si-perovskite tandem solar cells

HiPER-Ni

Highly efficient nickel-contacted Ag-free POLO2-IBC solar cells

Publications

Towards high-efficiency POLO IBC solar cells based on a PERC+ processing technology

Dullweber, T. and Mertens, V. and Stöhr, M. and Langlois, J. and Mettner, L. and Baumann, U. and Haase, F. and Brendel, R. and Libal, J. and Vogt, A. and Ambrosius, N. and Pernau, T. and Haverkamp, H.Firing-Stable PECVD SiOxNy/n-Poly-Si Surface Passivation for Silicon Solar Cells

Stöhr, M. and Aprojanz, J. and Brendel, R. and Dullweber, T.A Detailed Chemical Model for the Diffusion of Phosphorus Into the Silicon Wafer During POCl3 Diffusion

Jäger, P. and Mertens, V. and Baumann, U. and Dullweber, T.Industrial PERC+ solar cell efficiency projection towards 24%

Dullweber, T. and Stöhr, M. and Kruse, C. and Haase, F. and Beier, B. and Jäger, P. and Mertens, V. and Peibst, R. and Brendel, R.Evolutionary PERC+ solar cell efficiency projection towards 24% evaluating shadow-mask-deposited poly-Si fingers below the Ag front contact as next improvement step

Dullweber, T. and Stöhr, M. and Kruse, C. and Haase, F. and Rudolph, M. and Beier, B. and Jäger, P. and Mertens, V. and Peibst, R. and Brendel, R.Industrial implementation of 24%-efficient POLO IBC solar cells and future upgrade to 26%-efficient POLO 2 IBC

Dullweber, Thorsten and Larionova, Yevgeniya and Jäger, Philip and Mertens, Verena and Schimanke, Sabrina and Ripke, Melanie and Baumann, Ulrike and Osman, Alaa and Römer, Udo and Peibst, Robby and Brendel, Rolf and Cokun, Özlem and Çekerek, Gamze and ÇaliArslan, Meri((̧c and Gregory, Geoffrey and Hoffmann, Erik and Centazzo, MassimoContact person

Dr. Thorsten Dullweber

Head of PV department: Infrastructure