Development and demonstration of innovative, stagnation safe solar thermal systems with heat-pipes collectors

Contact

Bert Schiebler, Dipl.-Ing. (FH)

Tel.: +49 (0)5151-999 524

E-Mail: schiebler@isfh.de

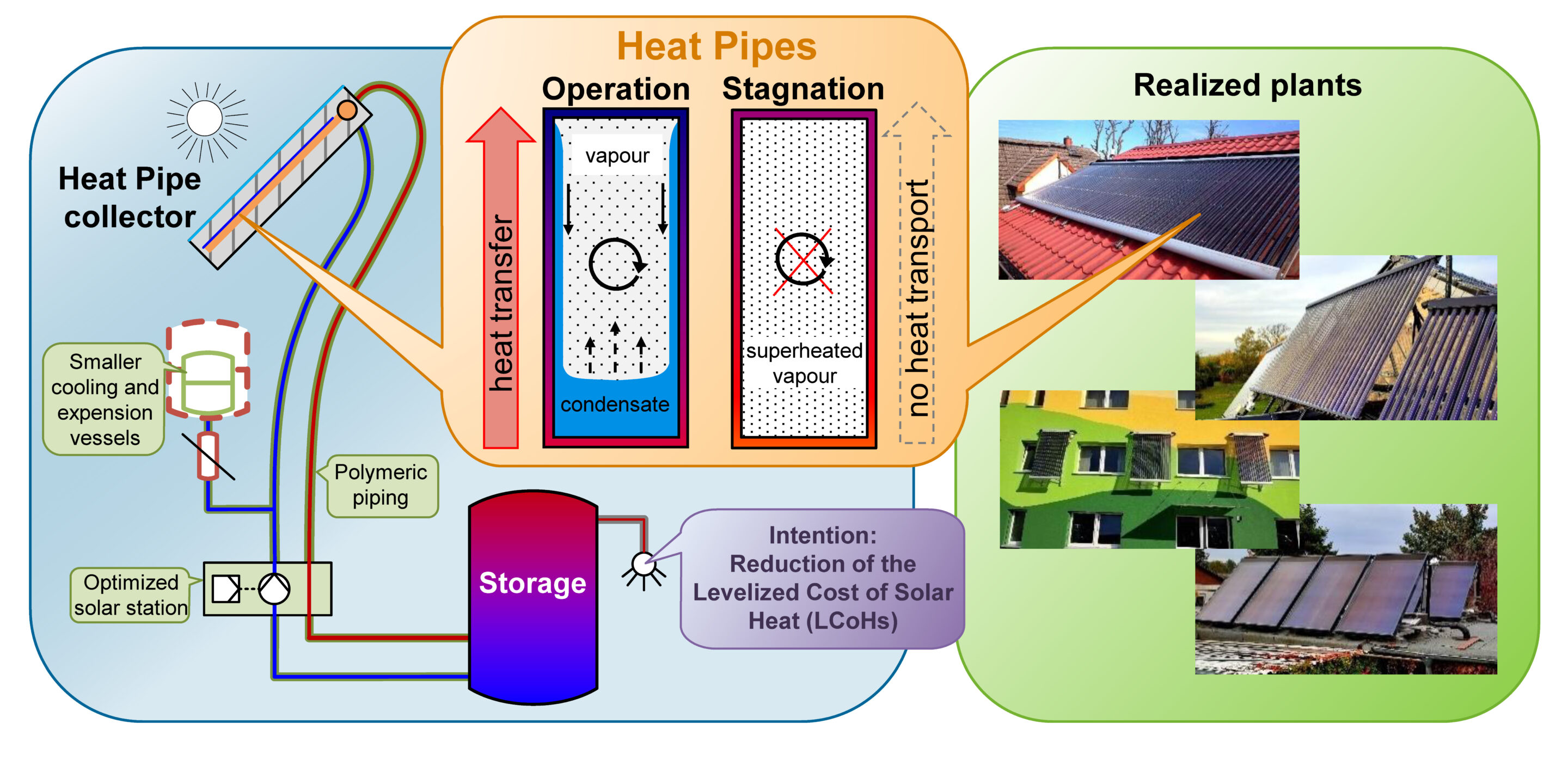

Schematic drawing of the heat pipes cross section in the operating range and in stagnation periods (center) as well as a proposed solar circuit configuration of a optimized solar thermal system with overheating prevention (left), which was realized in several demonstration plants (right).

Solar thermal systems are already well-established on the market as efficient renewable heat sources. High costs and high complexity, however, are major barriers to their dissemination and avoid the development of their large potential. New technical solutions are needed to improve their cost effectiveness and general acceptance. Novel solar thermal collectors with heat pipes are a promising approach for this purpose. A suitable design provides for a high efficiency in the operating range as well as for the reduction of thermal loads in stagnation mode. By exploiting the dry-out effect of heat pipes, the maximum solar circuit temperature can be limited to 125 °C. Preventing overheating in stagnation mode enables cost-effective system configurations with polymeric pipes, smaller designed expansion vessels and cost-optimized solar stations. Furthermore an easier installation process and low-maintenance operation can lead to a significantly higher profitability of such systems.

In the completed research project „HP-Koll“ (BMWi, FKZ 325550 A-C) heat pipe collectors for this purpose were successful developed and evaluated. The knowledge about their system behavior and economic benefits are based on tests under laboratory conditions, simulations and system cost estimations. The key issue of the ongoing project “HP-SYS” is to design novel solar thermal systems and to monitor these systems in the frame of field tests. The investigations focus on both flat plate collectors and evacuated tube collectors with heat pipes, which guarantee the prevention of high temperatures and the avoidance of evaporation in the solar circuit. The use of less expensive components as well as the smaller effort for installation and operation are expected to reduce the Levelized Cost of Solar Heat (LCoHsol) in comparison to typical solar systems with standard collectors by 20-30 %. Main goal of the ongoing project is to prove these first estimations.

The project is divided in two essential phases: At first new solar circuit components (pipes, solar stations) are investigated by means of laboratory tests. Furthermore novel system configurations with both flat plate and evacuated tube collectors are developed and comprehensively tested at ISFH. In the second phase, selected system configurations are realized in form of demonstration plants. The monitoring aims at evaluating the system performance, the behavior in stagnation mode and the suitability of the new components in real solar circuits as well as the economic benefits. The laboratory and field tests are complemented with extensive simulations targeting the analyses and description of the thermo-hydraulic properties of the considered systems.

Publications:

- B. Schiebler, F. Weiland, F. Giovannetti, O. Kastner, S. Jack: Improved flat plate collector with heat pipes for overheating prevention in solar thermal systems, Conference Proceedings, ISES Solar World Congress 2019, Santiago, Chile, November, 2019

- B. Schiebler, Julian Schumann, F. Giovannetti: „Experimentelle Bewertung von stagnationssicheren Flachkollektoren mit Wärmerohren zur solaren Trinkwarmwasserbereitung in Thermosiphonsystemen“, 30. Symposium Solarthermie und Innovative Wärmesysteme, Online-Konferenz 12.-14. Mai 2020

- J. Schumann, B. Schiebler, F. Giovannetti: „Bewertung verschiedener Rückseitenreflektoren in stagnationssicheren Vakuumröhrenkollektoren“, 30. Symposium Solarthermie und Innovative Wärmesysteme, Online-Konferenz 12.-14. Mai 2020

- B. Schiebler, D. Walentin, J. Schumann, F. Giovannetti: Experimental evaluation of stagnation-safe flat plate collectors with heat pipes for domestic hot water preparation in thermosiphon systems, Conference Proceedings, EuroSun Conference 2020, Online, September, 2020

- B. Schiebler, D. Walentin, S. Tan, J. Schumann, F. Giovannetti: „Bewertung einer Solarthermieanlage mit stagnationssicheren Wärmerohrkollektoren in einem innovativen Systemkonzept“, 31. Symposium Solarthermie und Innovative Wärmesysteme, Online-Konferenz 27.-29. April 2021

- Schumann, J.; Schiebler, B.; Giovannetti, F.: “Performance Evaluation of an Evacuated Tube Collector with a Low-Cost Diffuse Reflector”, Energies, Bd. 14, Nr. 24, https://doi.org/10.3390/en14248209 , 2021

- Jensen, J.; Schiebler, B.; Giovannetti, F.: „Simulationsstudie stagnationssicherer Wärmerohrkollektoren – Vergleich zwischen Simulation und Praxis“. Konferenzbeitrag 32. Symposium Solarthermie und Innovative Wärmesysteme, Bad Staffelstein, 3.-5. Mai 2022

- Schiebler, B.; Wagner, L.; Jensen, J.; Giovannetti, F.: „Innovatives Systemkonzept mit stagnationssicheren Wärmerohrkollektoren im Praxistest“: Ergebnisse aus den Feldtestanlagen. Konferenzbeitrag 32. Symposium Solarthermie und Innovative Wärmesysteme, Bad Staffelstein, 3.-5. Mai 2022

- Schiebler, B.; Beier, T.; Köhler, J.; Jensen, J.; Giovannetti, F.: „Projektabschluss HP-SYS: Entwicklung und Demonstration innovativer, stagnationssicherer solarthermischer Anlagen mit Heat-Pipe-Kollektoren“. Konferenzbeitrag 32. Symposium Solarthermie und Innovative Wärmesysteme, Bad Staffelstein, 3.-5. Mai 2022

- Jensen, J.; Schiebler, B.; Giovannetti, F: “A TRNSYS Type for the simulation of temperature limiting heat pipe collectors”, Conference Proceedings, EuroSun-Conference, Kassel, 25.-29. September 2022 (in press)

- Schiebler, B.; Köhler, J.; Wagner, L.; Jensen, J.; Giovannetti, F.: „Heat pipe collectors with overheating prevention in a cost-optimized system concept: Monitoring of system performance and stagnation loads under real conditions”, Solar Energy Advances, Bd. 3, S. 100040, https://doi.org/10.1016/j.seja.2023.100040 , 2023.

- Schiebler, B.; Jensen, J.; Giovannetti, F.; Rompel, A.: Entwicklung und Demonstration innovativer, stagnationssicherer solarthermischer Anlagen mit Heat-Pipe-Kollektoren, Abschlussbericht FKZ: 03ETW005, ISFH, 2022

Industry partner

AKOTEC Produktionsgesellschaft mbH, Grundmühlenweg 3, 16278 Angermünde, Germany

![Akotec-Logo-rgb-300dpi [:de]Logo AKOTEC[:]](https://isfh.de/wp-content/uploads/2020/08/Akotec-Logo-rgb-300dpi.png)

KBB Kollektorbau GmbH, Bruno-Bürgel-Weg 142-144, 12439 Berlin, Germany

Duration of the project

Overall: 01.11.2018 – 31.05.2022

KBB-part: 01.11.2018 – 29.02.2020

Funding

The project”Development and demonstration of innovative, stagnation safe solar thermal systems with heat-pipes collectors ” underlying this publication is funded by the German Federal Ministry of Economy and Climate Action (reference number 03ETW005A-C) based on a decision of the German Parliament. The authors alone are responsible for the content of this publication.