POLO – Joint project: Elegant combination of local doping processes and Si deposition techniques for cost-efficient fabrication of poly/monocrystalline Si contacts

Contact

Prof. Dr. Robby Peibst

Tel.: +49(0)5151-999 313

E-Mail: peibst@isfh.de

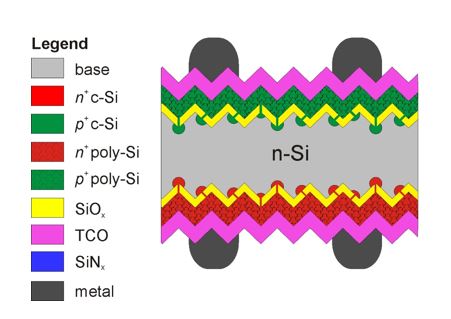

The main reason for current improvements in energy conversion efficiency of industrial-type solar cells is the reduction of recombination losses. By improving wafer quality and surface passivation recombination at the metal contacts has become more and more dominant, as this recombination is difficult to minimize for homojunction silicon solar cells that feature a pn-junction inside the crystalline silicon.

A promising approach to minimize contact recombination, which is already used in the semiconductor industry, is to move the highly doped regions out of the crystalline (c-) silicon substrate into polycrystalline (poly-) silicon layers deposited on top of the substrate. The main challenge in applying this technique of poly-Si/c-Si junctions to photovoltaics is its integration into a lean process flow that meets the stringent cost pressure of PV production. Since the poly-Si layers on the front and rear side of the solar cell need to be doped differently (p- and n-type, respectively), one either needs a single-side deposition technique for the poly-Si or a simple way to combine a double-side poly-Si deposition with a single-side doping method.

The aim of the project is to combine innovative techniques of poly-Si deposition and local doping to achieve energy conversion efficiencies >23% with a comparable number of processing steps as today’s state-of-the-art solar cell technologies.

Partners

Associated industry partner

Duration of the project

01.08.2014 – 31.12.2017

Funding

The project is funded by the Federal Ministry for Economic Affairs and Energy under grant no 0325702A. The responsibility for the content of this publication lies with the authors.