Development and evaluation of an uncovered modular photovoltaic-thermal collector based on a mounting system with integrated construction

Contact

Dr.-Ing. Federico Giovannetti

Tel.: +49 (0)5151-999 501

E-Mail: giovannetti@isfh.de

Optimization based on numerical modelling

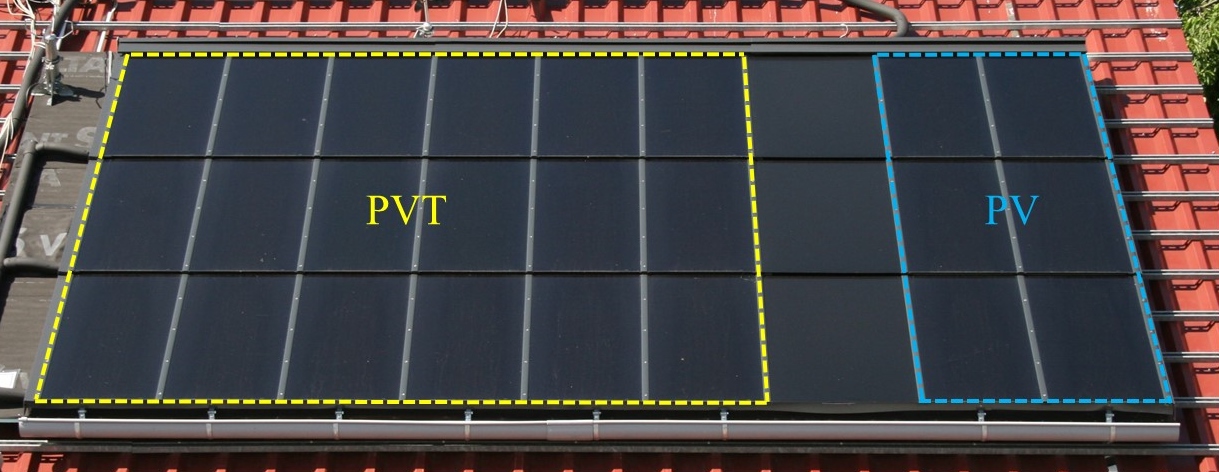

On a test roof of the ISFH we installed a 20 m2 prototype (including 14 m2 PVT) for performance measurements and usability tests. Figure 1 shows the prototype on the wooden roof substructure specially constructed for authentic measurement results. The system is connected to a heat pump system and is operated with a 30% ethylene glycol mixture in order to adjust low collector inlet temperatures. In addition to the sensors required for power measurements, numerous temperature sensors on the collector and roof surfaces as well as measuring equipment for the recording of electrical string voltages and currents were installed.

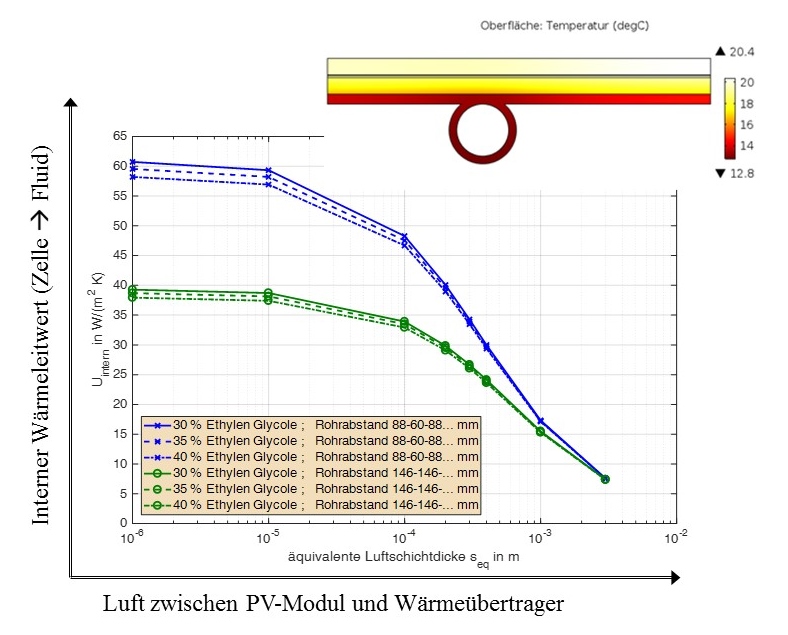

Using numerical modelling, the heat transport through the continuous casting profile is optimized to the greatest possible extent. Based on the same method, we classified the thermal connection between PV cells and heat exchangers prevailing on the installed prototype. Due to insignificant air inclusions, the detachable connection shows nearly optimal thermal bonding and high thermal efficiencies in measurements and simulations.

Industrial partners

Elodrive GmbH, Nussbaumweg 23, 51503 Rösrath

Boulevard der EU 7, 30539 Hannover

Duration of the project

01.04.2015 – 14.09.2017

Funding

The project “ModulTech – Solarhybrid” underlying this publication is funded by the German Federal Ministry of Economy and Energy (reference number 16KN041920) based on a decision of the German Parliament. The authors alone are responsible for the content of this publication.