Unsere Forschung

Herzlich willkommen am niedersächsischen Institut für Solarenergieforschung (ISFH)!

Die Energiewende braucht die Solarenergie. Solarenergie schont unser Klima, ist überall verfügbar, ist bei der Bevölkerung beliebt und erzeugt Strom und Wärme nahe dem Ort des Energiebedarfs. Und: Der weltweit rasante Ausbau der Solarenergie birgt große wirtschaftliche Chancen für unser Exportland!

Seit mehr als 30 Jahren fördern wir die Nutzung der Solarenergie durch unsere angewandte Forschung und die Ausbildung junger Menschen in den Bereichen „Photovoltaik“ und „Solare Systemtechnik“. Dabei ist „Innovation mit Wirkung“ unser Motto. Wir kooperieren intensiv mit der Industrie, mit anderen Forschungseinrichtungen und Universitäten und sind ein An-Institut der Leibniz Universität Hannover.

Wir freuen uns auf Ihre Anfragen, sei es als möglicher Forschungspartner aus der Industrie oder als Kunde unseres Dienstleistungsangebots oder in Form Ihrer Bewerbung für eine der ausgeschriebenen akademischen Abschlussarbeiten und Stellenangebote. Ihre Ideen zählen!

Neue Publikationen

Cell-to-module factors of perovskite/silicon tandem and silicon single junction mini modules for different module rear sides

Brockmann, T. L. and Blankemeyer, S. and Kirner, S. and Peibst, R. and Wietler, T. and Schulte-Huxel, H.Selective laser ablation of single layers from SiO2/poly-Si superlattices for patterning of 26 % efficient IBC solar cells

Römer, Udo and Rienäcker, Michael and Peibst, RobbyFalling costs for battery storages make facade photovoltaic systems more attractive for prosumers

Bredemeier, Dennis and Mahner, Alexander and Wietler, Tobias and Niepelt, Raphael and Brendel, RolfIndustrial implementation of 24%-efficient POLO IBC solar cells and future upgrade to 26%-efficient POLO 2 IBC

Dullweber, Thorsten and Larionova, Yevgeniya and Jäger, Philip and Mertens, Verena and Schimanke, Sabrina and Ripke, Melanie and Baumann, Ulrike and Osman, Alaa and Römer, Udo and Peibst, Robby and Brendel, Rolf and Cokun, Özlem and Çekerek, Gamze and ÇaliArslan, Meri((̧c and Gregory, Geoffrey and Hoffmann, Erik and Centazzo, MassimoThermally active rear-ventilated façades: Numerical modelling and experimental validation

Frick, E. and Kirchner, M. and Kabelac, S. and Giovannetti, F.Forschung am ISFH

Siliziumsolarzellen und -module

Vom Silizium-Wafer bis zum PV-Modul: Unsere Forschung vereint Materialverständnis, Zell- und Modultechnologie, Qualitätssicherung und Fertigungstechnik für eine hocheffiziente, kostengünstige und ressourcenschonende Photovoltaik-Produktion.

Gebäudeintegration

Gebäudeintegrierte Solarthermie, Photovoltaik und Photovoltaik-Thermie – funktional, ästhetisch und effizient. Wir entwickeln Lösungen für Fassaden, Dächer und neue Energieanwendungen.

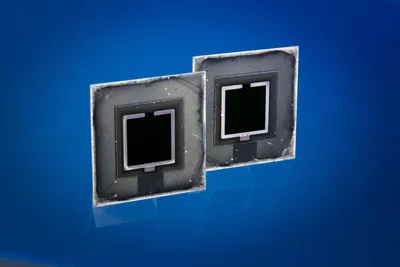

Tandemsolarzellen und -module

Wir entwickeln innovative Tandemsolarzellen-Konzepte mit Fokus auf höchste Effizienz, industrielle Umsetzbarkeit und die Reindustrialisierung der PV-Produktion in Europa.

Gebäudeenergiesysteme

Innovative Energiesysteme für Gebäude: intelligent vernetzt, solar unterstützt und bereit für die klimaneutrale Zukunft.

Fertigung und Spezialproduktion

Wir entwickeln am ISFH digitale, flexible und kosteneffiziente Technologien für die Produktion von Solarzellen und (maßgefertigten) PV-Modulen.

Wärmepumpen

Wir erforschen Wärmepumpen zur Versorgung von Gebäuden und Quartieren und thermischen Energiesystemen – mit Simulation, Komponentenanalyse und realen Praxistests.

Zuverlässigkeit von Photovoltaik

Wir prüfen, wie zuverlässig neue Solarzellen, Materialien und PV-Module unter realen Bedingungen funktionieren, sei es im Labor, Freifeld oder mit Spezialmodulen.

Wasserstoff

Wir bringen grüne Wasserstofftechnologie voran: durch neue Katalysatoren, innovative Materialien mittels Protonen-Austausch-Membran-(PEM)-Elektrolyse und Unterstützung der Industrie bei der Skalierung neuer Lösungen.

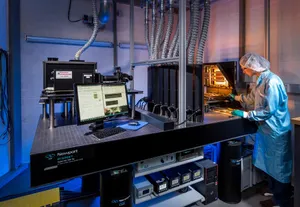

Unser Service im CalTeC

Als von der DAkkS anerkanntes Labor bietet das ISFH CalTeC präzise Kalibrierungen und Prüfungen für Solarzellen, solarthermische Systeme, Spektroradiometer und Wärmepumpen nach internationalen Normen wie ISO, IEC und EN. Neben akkreditierten Services unterstützen wir Sie auch mit individuellen Prüfungen und Entwicklungsbegleitung.

Haben Sie eine Frage zum ISFH?

Wir helfen Ihnen gerne weiter! Sie können die konkreten Ansprechpartner zu unserer Forschung kontaktieren oder uns über unseren allgemeinen Kontakt erreichen.